Our world has become increasingly interconnected over the last eighty years. The core of such connection has been the evolution of supply chains, from local self-sufficient production to global production, in which a single phone contains components designed in the United States, produced across East Asia and often assembled in China. Such interconnection has shown to the be strength of the global economy over the last twenty years, resulting in a marked increase in global GDP. While experiencing such growth, we have often not considered the wide-reaching consequences of a local pandemic on the global supply chain, largely because of the bullish beliefs of global actors during periods of sustained growth. But after all these years, we have finally been forced to confront the dangers of a global supply chain, particularly one so reliant on a specific country for the majority of its production and consumption.

History of the Global Supply Chain

The most pertinent historical example of a truly global supply chain was the Silk Road throughout Asia. However, the cost and time taken in long distance trade was a significant barrier to entry, therefore trade was limited to highly expensive and high demand goods such as spices, weapons and other luxury goods such as silk. Therefore, the production and consumption of goods was predominantly local. Markets were based in individual settlements, in which each city contained a variety of producers who produced quite little amount of goods.

The first truly global supply chain was that of the triangular trade of the 1700s. The advancements in shipping technology reduced the cost of international trade by allowing large fleets of ships to carry a significant amount of goods. Slave Labour was exported from West Africa to the United States, who then produced the products exported from the United States to Europe. European sailors were the ones who partook in the trade, purchasing African slaves in return for weaponry and other industrial goods. They then sold the slaves and purchased the agricultural goods to sell back in Europe. Such a supply chain was the basis of the interconnected global supply chains we see today.

Significant advances in transportation during the 1800s allowed for the expansion of the global supply chain. Steamships, railways and the advent of infrastructure projects such as the Suez Canal allowed for the advent of a truly global chain of supply. Britain’s use of colonies for the production of raw goods, then as consumers of their industrial goods highlights the first true example of a global supply chain. Cotton produced in India was being shipped to Britain after the physical destruction of the Indian Textile Industry. The British refined the cotton and produced textiles in places such as Manchester, then sold the clothes produced across their colonial markets. The macabre irony of the British selling imported goods in the place of destroyed domestic industries highlights the impact of colonialism on the modernisation of the supply chain.

Post World War 2, the capitalist nations of the world experienced a significant amount of globalisation, a product of a groundswell of public support for increasing global influence of significant powers such as the United States. Moreover, there were significant, yet often overlooked innovation into the logistics of foreign transportation. The containerisation of shipping significantly reduced the cost of international transportation of goods by creating a simple method for the sorting and transporting of like goods in large crates. Therefore, port handling costs dropped drastically and shipping became a very viable option as it is today.

The final piece of modern supply chains is the highly advanced communication networks that were built. Innovations such as faxes, the email allowed the communication of exact specifications of the goods ordered in a timely manner that can be sent all over the globe. Therefore, the production process could become increasingly modularised (where goods and services are produced in different places and then assembled together to make the final product).

Today, we live in a world where all these innovations have come together where goods are produced in East Asia, shipped to an Amazon warehouse in the United States then back to the consumer in Australia within a week. All these advances combined have greatly increased the efficiency of the global economy in the 21st century.

Advantages of the Global Supply Chain

The global supply chain allows businesses to take advantage of specialised manufacturing in markets that have a competitive advantage over similar manufacturing in other countries. Modern supply chains often involve design, research and development in the United States, the EU, Japan and South Korea, where the world’s best minds are often attracted due to higher salaries and better educational systems domestically. These advantages ensure that businesses are always finding new ways to stay ahead of their competitors in the industry by constantly innovating and finding creative ways to better their rivals. However, simple manufacturing components of these products occurs in developing economies in South East Asia, Africa or Mexico, where a blend of improving infrastructure, yet low wages allows businesses to produce products both efficiently and at low prices. However, the more advanced manufacturing occurs in more developed economies such as China, which now contains a greater number of skilled workers who can produce more complex goods efficiently and capably. These products are all assembled in a variety of places where labour is relatively inexpensive.

Manufacturing products in places in which they are most efficient reduces the cost of production for businesses while also maximising quality of output in the design stage as well as with advanced manufacturing. These competitive advantages have resulted in the solely ‘homegrown’ and then locally consumed model of business as obsolete, as local producers can rarely compete with goods produced overseas, often due to lower prices or quality.

The global supply chain has also resulted in the increased efficiency on the demand side as well. Local businesses now have access to the global market in virtually all sectors, including agriculture. Therefore, business can now export goods and services to larger markets across the world. For a country like Australia, with a surplus of natural resources and arable land, the power of access to the global supply chain is even more powerful. As Australia is domestically a small market, often highly competitive industries will be fighting for a relatively small raw market share (number of people who buy their products in the industry) and the number of goods they can sell is inherently capped. Such a system limits economic growth by the fact that there merely are not enough people in Australia to consume all of the great products we make. That’s where Australia’s access to the Asian market comes in. The Asian middle class is growing and demanding more goods and services than ever before. High quality Australian goods and services are coveted in Asian markets, which provide a huge additional market for our goods and services. Such added demand allows Australia to produce and sell more goods and services, thereby improving our economic growth by greater degrees than if we didn’t have access to the global market.

Disadvantages of the Global Supply Chain

The ‘Coronavirus Crash’ has highlighted the key issues with the China-centric supply chain on both the supply side and demand side of modern businesses. China has become the number 1 producer and consumer of goods and services in the world. Therefore, the world’s business relies significantly on China for the production of goods and services that are sold, as well as demand for the goods that they produce. However, the world has failed to consider the possibility of a significant crisis in China which could halt the transportation of goods, as has occurred recently with the Covid-19.

On the supply side, businesses are unable to obtain inventory produced in China. The global supply chain is so reliant on China that the majority of products that stock Australian shelves have components that were produced in China. Therefore, as China goes into some level of lockdown, businesses across the world are unable to access the goods that they wish to sell. An example is Cotton On here in Australia, who produce the majority of their apparel in China. Stores are worried that they will literally run out of stock within the next three months, the ultimate doomsday scenario for the Australian economy. If apparel and other retailers are unable to access their stock from China, retail consumption will grind to a halt, resulting in significant contractions in the Australian economy. Much of economic growth is reliant on consumer consumption, therefore the widespread inability to sell goods produced in China would result in an unprecedented economic contraction. Such doomsday scenario could have been averted with forward thinking business approach, as I will detail later.

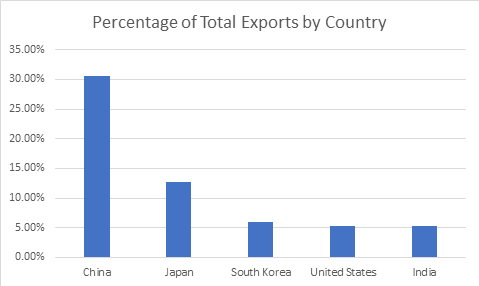

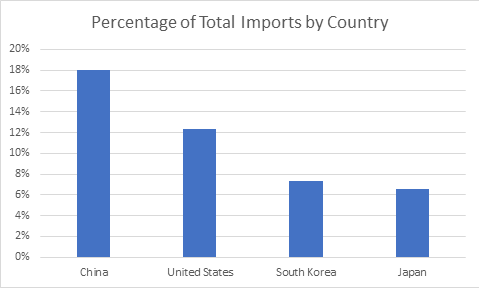

Businesses across the world are increasingly reliant on the burgeoning Chinese market to sell the majority of their products. Significant amounts of Australian natural resources, agriculture and other goods are exported to China every day. Australia is very reliant on Chinese consumers for the sale of our goods and services. Due to the shutdown of significant parts of the Chinese economy due to the lack of public movement within cities, demand for Australian products will significantly decrease. For example, Australian wine, rather coveted in China, will be less in demand due to the demise of Chinese restaurants as a result of the relative lockdown – either mandated or voluntary – in many Chinese cities. Not only is wine less in demand, but the export of wine will be held up in ports, therefore it is not possible to guarantee the shipment of wine to the customer due to stricter Chinese customs. While wine is less affected by such holdups, fresh produce such as meats, fruits and vegetables would grow stale before reaching their customers. Due to Australia’s significant reliance on China for exports (as shown in graph below), if there is a significant reduction in demand for Australian products within China, the consequences could be dire.

Creating a Sustainable Global Supply Chain

The flaws of a China-centric supply chain on both the demand and supply side puts all the globe’s eggs in one basket. As we could see in the coming months, there global economy could end up with egg on its face as a result of short-sighted business planning to maximise profits in the short term. Instead, to ensure a sustainable global supply chain that takes advantage of the efficient manufacturing of the global south must be based on the diversification of production and demand. China’s disproportionate influence on the global economy creates an economy prone to collapse when China is in crisis. Therefore, the diversification of both exports and imports is essential.

Global production is experiencing significant diversification over the past five years, coinciding with slowing growth in the Chinese economy. As the Chinese middle class becomes increasingly educated and demanding higher wages, businesses have transitioned low skill manufacturing to other regions. In our Asia-Pacific region, Bangladesh has become a larger manufacturer of textiles and automated manufacturing of industrial goods have moved to places like Vietnam, who now possess a market advantage over China in the production of industrial goods, having the ability to produce similar quality goods at lower prices. Automation of the production process allows some manufacturing to move back to developed countries, with some car manufacturers still producing cars in developed economies such as Japan and South Korea. Automated manufacturing allows production plants to require fewer low skilled workers, instead requiring a smaller number of high-level technicians to manage the automated production equipment.

Australia has been relatively successful at diversifying its imports compared to its exports, with China only being the source of 18% of Australian imports. However, multinational companies who are heavily involved in Chinese production are struggling to gain access to their inventory produced in China. Therefore, Australia should likely encourage the import of products from our other Asian partners such as Vietnam, Indonesia and India to diversify the source of our production. Strengthening the Trans-Pacific Partnership, even without US involvement, could result in more diversified import of goods to Australia, thereby maintaining the supply of our goods and services during times of crisis.

Diversifying the demand for global products is a significant challenge for the global economy. Changes in policy by Government or businesses is unable to change areas in which consumers demand specific products. However, diversifying the production of our goods and services would likely have the knock-on effect of lifting many in these countries out of poverty. As occurred in China, these now middle-class consumers will demand more discretionary products as well as infrastructure expansion. These expansions will increase the demand for global commodities, such as our Iron Ore, as well as luxury goods.

Therefore, the diversification of supply and demand are inherently interconnected. To find a future where the global economy can withstand the shocks that are common throughout history, we must promote diversification and forward-thinking trade policies, from both businesses and governments, rather than short-term profit-driven production in the cheapest possible market. Diversifying global production helps these same businesses in the long run by providing more middle-class consumers who would be able to afford their products, thereby improving global demand for goods and services. Creating long-term economic growth can no longer be the product of the success of one or two nations, as it has been post WW2, but the success of all nation, collectively buying and selling each other’s products with fewer barriers to trade and taking greater advantage of each nation’s competitive advantage.

Conclusion

The advent of the truly global supply chain coincided with a period of significant economic advancement for the world as a whole. Taking advantage of the entire world in the pursuit of technical efficiency truly was one of the most influential economic decisions of the last fifty years. However, the system exacerbated the inequality of the global economy, concentrating power in the world’s two largest economies, the United States and China as both producers and consumers. Such concentration of power has resulted in what we see today as the ‘Coronavirus Crash’, in which Chinese lock-down has wiped billions of dollars off stock markets around the globe and heightened already prevalent fears of global recession. As a result, we as a nation, as well as the world as a whole, must act to diversify the supply of our goods and services out of China and into other developing countries. Not only does such action protect our supply from shocks such as the Coronavirus, it emancipates millions from poverty, thereby creating greater demand for discretionary products as the global middle class expands. Therefore, diversifying global production not only ensures the supply of goods and services that are the centre of all economies, but also creates additional demand from a growing middle class, ensuring global prosperity in the long run.

Sources

https://www.abc.net.au/news/2019-01-15/china-economy-slowdown-will-affect-australia/10716240

very educational!! good job! 💕💖😎👍😃

LikeLike

Great analysis the advantages and disadvantages of the global supply chain, and the over-reliance of Australia on Chinese consumers to purchase Australian products.

LikeLike